Zhongshan IPS Electric Factory

Your request our pursuit

We never say that our product is the best, because we know only the suited is the best. Whether it is good or not, should not be judged by what we say, but by what we do.

Our development team members have many years of practical experience in their respective fields and keep a keen sense of the latest technology trends and developments. Our development team encourages innovative thinking and novel solutions to meet customers' changing needs and market trends.

Our development team members have many years of practical experience in their respective fields and keep a keen sense of the latest technology trends and developments. Our development team encourages innovative thinking and novel solutions to meet customers' changing needs and market trends.

Our development team members have many years of practical experience in their respective fields and keep a keen sense of the latest technology trends and developments. Our development team encourages innovative thinking and novel solutions to meet customers' changing needs and market trends.

Our development team members have many years of practical experience in their respective fields and keep a keen sense of the latest technology trends and developments. Our development team encourages innovative thinking and novel solutions to meet customers' changing needs and market trends.

Our mold shop is equipped to design, manufacture, and repair a wide range of molds. We own over 100 molds, with at least 3-4 new molds added annually. We can tailor solutions to your requirements and specifications, ensuring our molds meet high quality standards.

Our mold shop is equipped to design, manufacture, and repair a wide range of molds. We own over 100 molds, with at least 3-4 new molds added annually. We can tailor solutions to your requirements and specifications, ensuring our molds meet high quality standards.

The injection molding workshop produces electric lunch boxes and small household appliances. By using automation, semi-automation and assembly line production, we are able to achieve batch and large-scale production, improve production capacity and output, save time and costs, and meet customer needs more quickly.

The injection molding workshop produces electric lunch boxes and small household appliances. By using automation, semi-automation and assembly line production, we are able to achieve batch and large-scale production, improve production capacity and output, save time and costs, and meet customer needs more quickly.

Our assembly workshop has many years of experience and expertise dedicated to product assembly and assembly. We have a skilled team who have extensive experience in the field of assembly and assembly and are familiar with the assembly requirements and process flows of various products.

Our assembly workshop has many years of experience and expertise dedicated to product assembly and assembly. We have a skilled team who have extensive experience in the field of assembly and assembly and are familiar with the assembly requirements and process flows of various products.

Quality control is our top priority in our packaging workshop. We strictly follow the ISO quality management system and adopt a strict inspection process to ensure the quality and integrity of each product's packaging. We use high-quality packaging materials and conduct packaging effect and durability tests to ensure that the product is fully protected during transportation and storage.

Quality control is our top priority in our packaging workshop. We strictly follow the ISO quality management system and adopt a strict inspection process to ensure the quality and integrity of each product's packaging. We use high-quality packaging materials and conduct packaging effect and durability tests to ensure that the product is fully protected during transportation and storage.

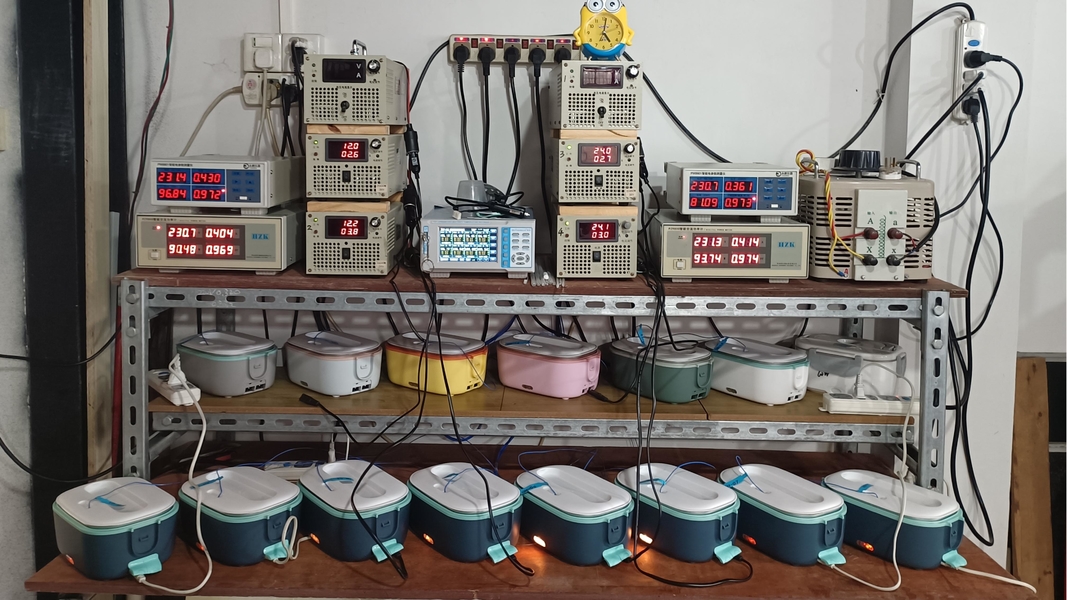

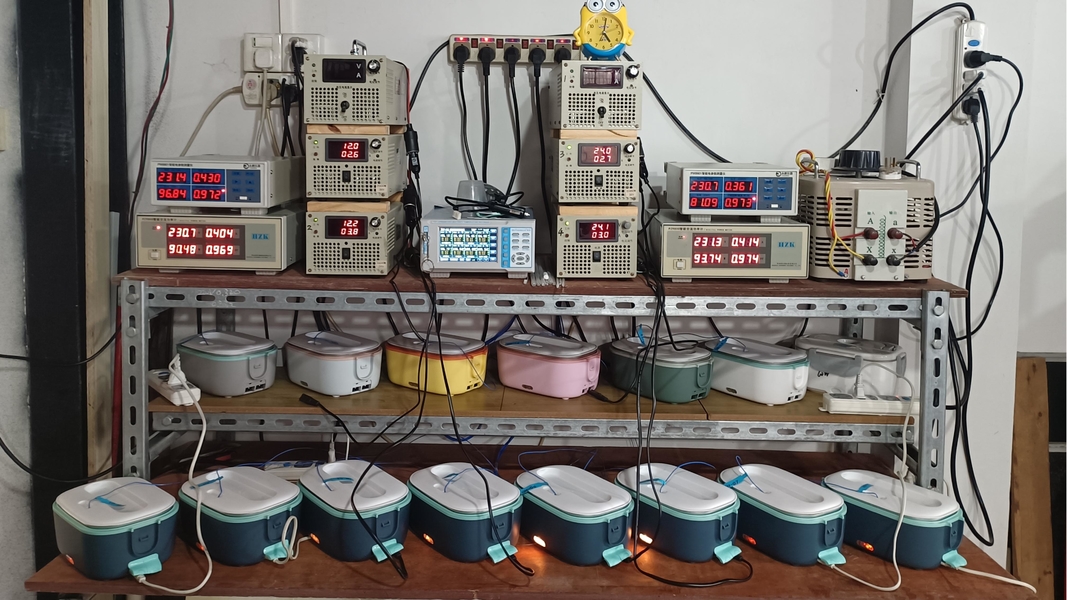

We use advanced temperature testing equipment and instruments to perform temperature quality inspections on our products to ensure that they are operating effectively.

We use advanced temperature testing equipment and instruments to perform temperature quality inspections on our products to ensure that they are operating effectively.

We use advanced professional high-voltage testing equipment to perform high-voltage tests on products. Monitoring equipment and data recording systems monitor and record the performance parameters and safety conditions of products under high-voltage conditions in real-time.

We use advanced professional high-voltage testing equipment to perform high-voltage tests on products. Monitoring equipment and data recording systems monitor and record the performance parameters and safety conditions of products under high-voltage conditions in real-time.

During the product aging test process, quality control is our focus. Our strict measures ensure the accuracy and reliability of the test. We regularly calibrate the test equipment and conduct quality audits and verifications to ensure the credibility of the test results.

During the product aging test process, quality control is our focus. Our strict measures ensure the accuracy and reliability of the test. We regularly calibrate the test equipment and conduct quality audits and verifications to ensure the credibility of the test results.

Our quality inspection includes purchased parts to ensure they meet our quality requirements. We use advanced equipment and instruments to detect potential problems in advance, reduce defect rates, and ensure the reliability and performance of purchased parts.

Our quality inspection includes purchased parts to ensure they meet our quality requirements. We use advanced equipment and instruments to detect potential problems in advance, reduce defect rates, and ensure the reliability and performance of purchased parts.

Detail Information

Main Market:

North America

, South America

, Western Europe

, Eastern Europe

, Eastern Asia

, Southeast Asia

, Middle East

, Africa

, Oceania

, Worldwide

Business Type:

Manufacturer

No. of Employees:

100~200

Annual Sales:

1500000-30000000

Customers Served:

Free labeling service

Detail Description

Zhongshan IPS Electric Factory was established in 2000, located in Zhongshan City, Guangdong Province. Focusing on the R&D and production of small household appliances for 25 years, through continuous efforts, the current factory area is more than 6,000 square meters, with an automated production workshop and 5 assembly lines with an annual output of more than 500,000 units. The factory has passed ISO-9001; many products have passed CE, ROHS, LFGB, FCC, UKCA, etc.

Our main products are lunch boxes, electric lunch boxes, mini rice cookers, electric mixers, bottles, tableware, etc.

In the past five years, through continuous innovation, we have over 20 original design products from Europe and America and become a top ten brand supplier of kitchen appliances on Amazon.

Introduction to IPS Factory

Technical Production Department

IPS specializes in the production of electric lunch boxes, boasting over 100+ proprietary molds and 11+ fully automatic injection molding machines, enabling efficient assembly line operations. Leveraging patented technology, IPS rigorously implements 12 quality inspection processes, coupled with hourly inspections and full employee self-inspections for dual quality control, ensuring zero defects and supporting large-scale customized production.

Full-Chain Quality Control System:

- Mold R&D Advantages: A library of over 100+ mature molds enables rapid prototyping and shortens lead times.

- Scaled Production: 11+ injection molding machines operate in parallel – ensuring a stable supply and a daily production capacity of 10,000 units.

- Raw Material Incoming Inspection (strictly selects food-grade PP raw materials)

- 12 Quality Inspections During the Production Process (including key indicators such as dimensions, sealing, and temperature resistance)

- Dynamic Inspections (on-duty engineers conduct hourly inspections of key indicators)

- Full-Staff Quality Inspection (operators conduct real-time quality checks and record every process).

- Patent Guarantee: Products are food-grade safety certified and offer industry-leading durability.

IPS Quality Management Department

The IPS Quality Management Department is the core of our company's quality control efforts. Through rigorous testing standards and comprehensive management processes, we ensure that every step of the process, from raw materials to finished products, meets the highest quality standards. Equipped with advanced testing equipment and specialized quality control instruments, we provide accurate data support for material screening, production and processing, and finished product inspection, ensuring high product reliability and stability.

Quality Control Process

1. Supplier Screening and Raw Material Inspection

- Prioritize long-term suppliers with consistent quality.

- All purchased raw materials must undergo rigorous testing and pass inspection before being released to the warehouse.

2. Quality Control During Production

- Products are tested during assembly to ensure compliance with standards at every stage.

- We implement a "one person, one machine, one responsibility" system, with workers directly responsible for equipment quality and recording test data.

3. Final Inspection Before Packaging

- After assembly, the Quality Management Department verifies test data to ensure compliance with delivery standards.

- Qualified products are transferred to the Packaging Department for standardized packaging.

4. Final Inspection Before Shipment

- Packaging integrity is checked to ensure compliance with export and customer requirements.

- After verification, products are moved to the finished product area for delivery.

The IPS Quality Management Department has full quality oversight authority and can conduct sampling inspections at any stage of production to ensure 100% product quality compliance.

Our goal: zero-defect delivery and customer confidence in every product!

IPS Electric Lunch Box Packaging Process

Standardized Packaging Process:

1. Label Verification

- Apply product labels in a standardized manner to ensure clear and accurate information.

2. Accessory Assembly

- Positioning and positioning the power cord after quality testing.

- Visually inspect each food-grade stainless steel inner container for defects and insert it precisely into place.

3. Sealing Quality Inspection

- Perform a 20% airtightness inspection after the lid is closed.

- Inspect the product exterior for scratches and stains.

4. Color Box Packaging

- Use shock-proof lining for standardized packaging.

5. Final Inspection and Sealing. 100% unpacking re-inspection at the end of the production line:

- Verify the completeness of accessories

- Check packaging integrity

- Verify shipping labels.

6. Qualified products are sealed and assigned a traceability code for storage

production line

IPS Factory Headquarters

IPS has 13 fully automatic production injection molding machines, 4 assembly lines, 5 mixing machines, product aging testing equipment, and several product testing machines.

The products are made of food-grade materials and go through at least 12 quality inspection procedures from raw materials-injection molding-assembly-packaging, so as to achieve 100% full inspection. And passed CE/ ROHS/LFGB/FCC/DGCCRF and other certifications. The products include electric heating lunch boxes, children's lunch boxes, electric cooking pots, electric kettles, and other small kitchen appliances, providing customized.

IPS Mold Branch

With a mold factory of 1,000 square meters, 2 mold design directors with more than 18 years of experience, 2 senior product structure designers, and 4 senior mold structure engineers.

Over the years, relying on the pursuit of new and innovative goals, and always adhering to the credibility and purpose of surviving on quality, we have embarked on a path of aggressiveness and steady development. IPS provides customers at home and abroad with drawings and samples to customize various molds, and has won wide acclaim and customer groups with excellent product quality. It has strong processing capabilities and excellent talents and welcomes new opportunities with a continuous spirit. and challenge.

IPS Hardware Division

IPS hardware semi-finished products use food grade 304 raw materials to produce electric heating lunch boxes, electric cooking pots, heating cups, and other hardware accessories of our products. The minimum order quantity is low, and the delivery time is fast. Welcome to map and customize.

Our Factory

IPS Quality Management Department

The IPS quality management department is an important control means for managing quality. It is equipped with the most advanced testing equipment and professional control devices, which can provide accurate reference data for selecting the most suitable materials and accessories, thereby effectively controlling the quality of the accessories. In addition, it provides engineers and quality control personnel with digital information to determine the feasibility of spare parts after processing.

This is the workflow of quality control.

Choose suppliers with stable quality. After purchasing raw materials, after testing, if they prove to be good, then we will arrange for these qualified materials to be put into storage.

When the product is being assembled, the product is tested at the same time. Each worker is responsible for his or her equipment. They will give you the actual test date and results. After proving that the testing date meets the delivery standards. Then the IPS Quality Management Department will send these devices to the packaging department to wait for packaging.

Before delivery, the IPS Quality Management Department should check the packaging condition of all products. If proven to meet export standards and customer requirements. They then move the equipment into the finished product area.

Of course, the IPS quality management department has the right to conduct sampling inspections at each production step to ensure product quality.

R&D

Research & Development

1. IPS design department: 2 mold design directors with more than 18 years of experience, 2 senior product structure designers, and 4 senior mold structure engineers. 100% ordered from the latest designs and then put into production lines.

2. IPS Production Department: All our workers have more than 7 years of craftsmanship to ensure that our products are of high quality at every point.

3. IPS production equipment: IPS has 13 fully automatic production injection molding machines, 4 assembly lines, 5 mixing machines, product aging testing equipment, and multiple product testing machines.

4. Welcome OEM and ODM orders!

More than 20 patented product molds

New food grade raw materials

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()